The Caisson Construction Method that can Match the Requestsof a New Construction Era

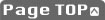

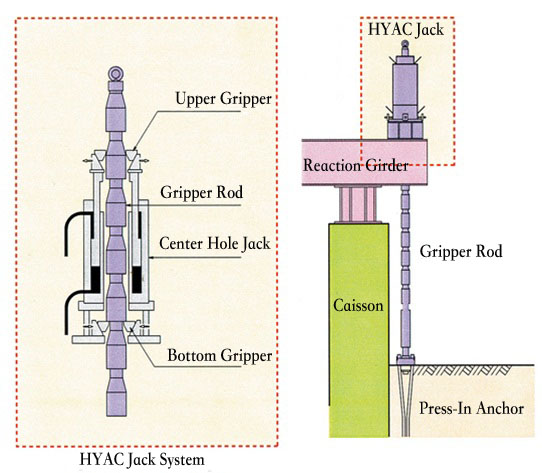

The HYAC Press-In Caisson method uses the reaction force from the ground anchor, transfers the Force through the Gripper Rod to the Hydraulic Jack, then forcefully Press-In Caisson by overcoming resistance force at the cutting edge and peripheral friction forces.

Special Features

●High Precision

Multiple Hydraulic Jacks can apply up to few thousands tons of Press-In

force on top of the caisson. High Precision Press-In is made possible by

skillfully operating the Hydraulic Jacks.

●Improved Control

The Press-In Caisson method uses relatively simple devices and yet it has

improved over the years. With improved excavation patten and Jack Control,

it has become a construction method that matches the requet of time and

provides solutions to various problems.

Construction Procedure

|

|

|

| Install Press-in Anchor | Prepare sufficient supportig surface, Place steel cutting edge |

Construction |

|

|

|

| Press-in, Excavation | Casting Underwater Concrete Slab |

Various Applications

- Bridge Foundation

- Vertical Shaft for Shield Tunnel or Underground Pipes

- Waterworks, Sewage Disposal(such as Pumping Stations, Machine Room,Distributing Reservoir, etc...)

- Reservoir used Emergency Measures・Regulating Reservoirs

- Underground Structure (Underground Car Park, etc...)

- U-shape Structure(River Improvement、Channel、Immersed Road、Aseismatic River Wall、etc...)

- Heavy Object Lowering and Lifting (Bridge Girder, Heavy Parts of Structure, etc...)

- Pressing Steel Segments into the Ground

HYAC Jack System

The proven Technology that makes impossible possible

|

|

|

| Anxious about deformation of peripheral ground |

Lacks construction Space | Lacks self weight for sinking |

|

|

|

| Require Vertical and Horizontal accuracy |

Lacks fund for other construction method |

Soft Ground without suitable Construction method |

Comparison with Other Construction Methods

| Caisson Method | Earth Retaining Excavation Method | ||||

|---|---|---|---|---|---|

| Construction Principal |

Method in which the main body, divided into lots, is first constructed at the ground level, pressed into the ground while the interior is excavated and the main structure is installed at the designed depth. | Method in which the main structure is built after excavating and leveling the floor while preventing the collapse of the ground using earth retaining walls and support construction. | |||

| Construction Method |

HYAC Press-In Caisson Method | Open Caisson Method |

Diaphragm Wall Method |

SMW Method |

|

| Summary | Method in which hydraulic pumps are used with ground anchors as reactive force and the frame is settled by Press-in into the ground. Underwater excavation is carried out below the water table. | Method in which only self weight of the Caisson is the only force to drive

the caisson downward. Large friction cut is designed in the outer diameter

to reduce friction. Underwater excavation is used. |

After excavating the trench and building the main structure, which serves as an earth retaining wall by means of RC column row pile, while protecting the porous walls by slurry pressure, the interior is excavated and the floor slab and walls are finished. | The ground is excavated with an auger and soil walls are constructed with H-beams as the core. With these as earth retaining walls, the interior is excavated and the main structure is constructed. | |

| Soil Conditions | Measures to prevent excessive sinking on soft ground are realized through

the segmentation of the construction into lots and forced penetration in

the ground. Press-in is possible without excessive excavation even in hard sandy gravel layer, where skin friction increases. The stability of the natural ground is not damaged since underwater excavation is performed. |

In order to reduce friction, sometimes crashed stone is used to backfill

between soil and the caisson. It doesn’t affect the stability of the soil, because it uses underground excavation. Sinking will face difficulties when encounter big rubbles and large rocks. |

Application is possible in virtually all types of ground as long it is

possible to protect the porous walls with slurry. It is not suitable for

ground in which porous walls collapse. For artesian water level or to prevent ground displacement, it is necessary to do chemical grouting under the slab, or secure extra penetration depth. The construction of supports is normally required along with the excavation and workability is poor. |

Excavation may not be possible if there are cobbles and boulders. For artesian water level or to prevent ground displacement, a response similar to diaphragm walls is required. Since there is less wall rigidity than with other construction methods, support construction is essential. Apprehension regarding water leaks also remains. |

|

| Construction Precision |

Since it is possible to individually control the press-in jack, the inclination

of caisson hardly occurs and posture corrections are simple. Vertical precision is about 1/500 or less. |

It difficult to keep the caisson upright, because it only uses self weight

as drivenforce. Vertical precision is less than 1/100. |

Since construction proceeds with guide walls installed and the walls are

finished later, construction precision is relatively good. Vertical precision is about 1/1000. |

||

| Construction Site |

Few temporary construction facilities are needed. The construction is possible as long as space can be secured for the clamshell and surplus soil equipment and little extra space. | Construction space can be very compact, because it does not need Press-In

Equipmnet. It uses self weitght to sink caisson. |

Space is required for excavator, accompanying crane, mud plant, reinforcing bar work yard, etc. | Though not as much as diaphragm wall, space is required for excavator, accompanying crane, plant etc. | |

| Since the main structure is constructed later, construction can start at the site where the main structure will be built if the project is large in scale. | |||||

| Space | Low spatial construction is possible. | Low spatial construction is possible. | Low spatial construction is possible (some equipment). | Low spatial construction is NOT possible. | |

| Work Environment |

Since most of the work is completed at ground level, the work environment is good and there it is not subject to the constraints. | Since most of the work is completed at ground level, the work environment is good and there it is not subject to the constraints. | Though cut and cover construction itself is carried aout in ordinary work

environments, it is necessary to take oxygen deficiency and noxious gases

into account as the depth increases. High-elevation work with considerable level disparities increases with the setting, removal, etc., of struts. |

||

| Construction Method |

HYAC Press-In Caisson Method | Open Caisson Method |

Diaphragm Wall Method |

SMW Method |

|

| Neighboring Structures |

This is suitable for neighboring construction since excavation proceeds while maintaining the water level, blocked off from the surrounding ground by leading penetration. | The stability of soil is difficult to control. Needs to take extra care during neighboring construction. |

There is relatively little impact on the surroundings since the walls adhere closely to the natural ground. | ||

| Noise & Vibration |

The push-in method itself generates no vibration or noise and low-noise construction can be realized depending on the selection of excavation equipment. | Low-noise construction can be realized depending on the selection of excavation equipment. | There is relatively little machine noise and vibration. | ||

| Underground Water and Gas |

There are no particular problems. | It’s difficult to control the movement the undergroud pipes. Needs to take extra care during construction. | There are no particular problems. | ||

| Safety | It is a static push-in method and it is very safe since there is no slippage of the gripper | Over sinking problem can occured and needs to be addressed. | It is a standard construction method and is very safe. | ||

| Construction Schedule |

Management of construction processes can be carried out based on a theoretical

subsidence relationship diagram. There are few temporary construction facilities and it is possible to shorten the construction term. |

Construction progress is difficult to control. Progress become incresingly slow as caisson sinks deeper into ground. |

Process management is effective. The construction term is relatively long. |

||

| Construction Cost |

It is simple, there are only few temporary construction facilities and construction costs are the lowest. | Thick uneconomical caisson wall is often designed to compensate for lack

of self weight for sinking. Extra cost occurs when self weight is insufficient to continue sinking the caisson. |

Equipment and construction costs are rather high and there is little advantage unless the project is large in scale. | Since the main structure is constructed later, the lift frequency increases as the depth increases due to support construction, which results in rather high costs. | |

| Construction Method |

HYAC Press-In Caisson Method | Open Caisson Method |

Diaphragm Wall Method |

SMW Method |

|